The impact wrench: A useful tool for special tasks

Anyone who has ever followed a car race has already seen this tool in action - the impact wrench. The impact wrench is not only in demand during pit stops in motorsport, however, when it comes to installing new tires on the racing car in a few seconds. The impact wrench is also used on construction sites and in one or the other DIY project, especially when long screws have to be screwed into metal or wood. How exactly such an impact wrench works, which types there are and when it plays an important role as a real special tool, we summarized for you.

How an impact wrench works

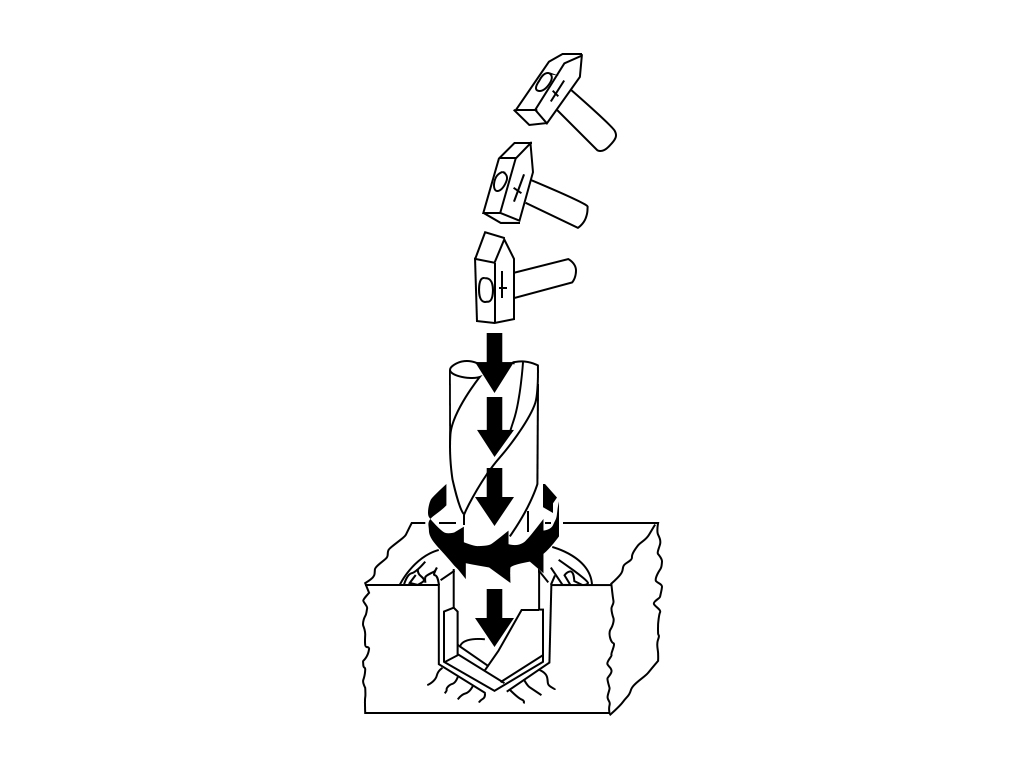

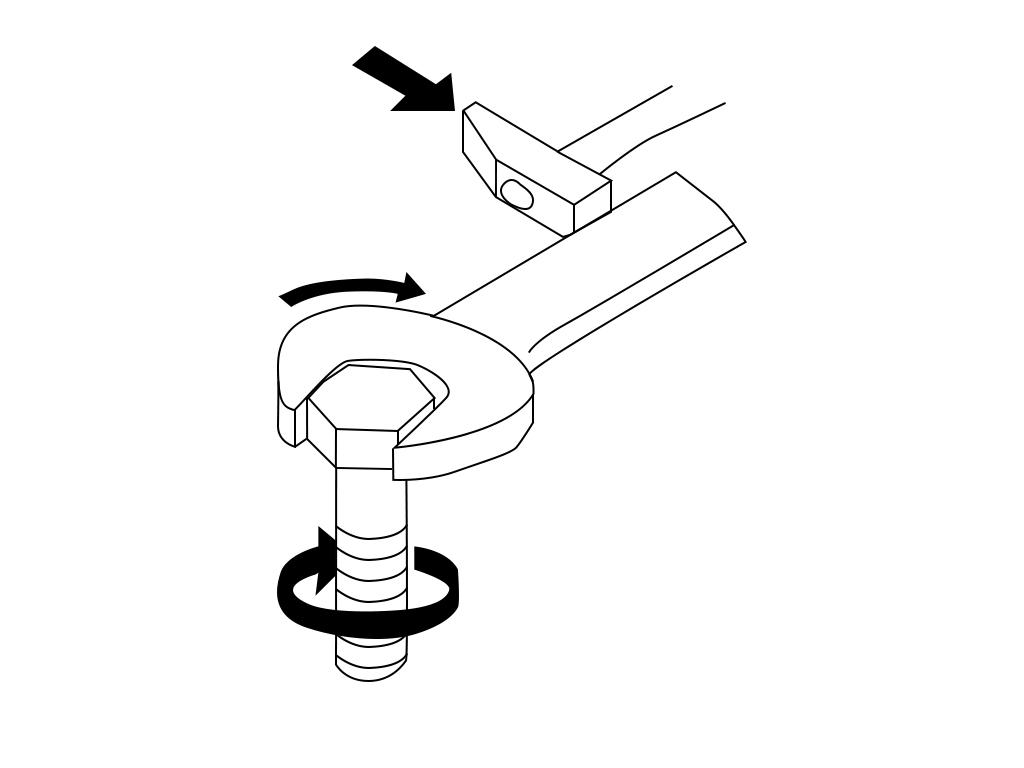

How an impact wrench, often and correctly also called a rotary impact wrench, works is actually explained by the name. Within the impact wrench, horizontal impacts are exerted in the direction of the rotary movement. This increases the torque with each rotary stroke. These torque peaks ensure that tyre bolts, for example, are loosened more easily. Due to the percussion mechanism, the devices are also relatively loud, but at the same time also maximally efficient.

Rotary impact wrenches are available in different versions, with different percussion mechanisms and motors, with rechargeable battery, compressed air or electric. With us you will find devices that are especially suitable for the DIY area, the ambitious craftsman or the hobby car mechanic.

The different types of impact wrenches

In our assortment you will find three different types of impact wrenches, which differ mainly in their drive type. Which model is best for you depends primarily on where you want to use the device.

Cordless impact wrenches

Our cordless impact wrenches are wireless and can therefore be used anywhere - which, by the way, is also their big advantage. Whether metal construction at great heights or a missing power connection, with the cordless impact wrenches you work as flexibly as possible. All you need is a Power X-Change battery and a charger to recharge your battery after work. Some of our cordless impact drivers are also equipped with innovative brushless technology. A brushless motor has the advantage that it is not subject to any mechanical wear, which makes it more durable and requires less maintenance than a brush motor.

Electric impact wrenches

If you are looking for an electric impact wrench, you will find it with us. In addition to the electric impact wrenches, which are conventionally connected to a socket for operation, a car impact wrench is also part of our range. This is plugged into the cigarette lighter in the car via a 12 V connection, for example, so that you can also change tyres on the go.

Compressed air impact wrenches

In many garages and workshops, so-called pneumatic impact wrenches can be found. As the name suggests, these devices only work with compressed air - so you need a compatible compressor to operate them. Although they are independent devices, compressed-air impact wrenches are therefore often part of the compressed-air accessories, because they would not be ready for use without a compressor. In the Einhell range you will find pneumatic impact wrenches with maximum torques between 340 and 610 Nm. The torque can be adjusted in various stages during tightening, i.e. in clockwise rotation. Incidentally, our air impact wrenches are supplied with accessories in a suitable case.

Impact wrenches are used here

Impact wrenches are not devices that you will use every day. Rather, they are experts in torque and, at up to 610 Nm, sometimes have 10 times the torque compared to very powerful impact drills. Due to the special mode of operation, namely a pulsating rotary movement, the torque in the tip becomes significantly higher. With this powerful rotary movement, fixed screws and nuts can also be loosened, but also very long screws can be screwed in. Impact wrenches are therefore used wherever strong rotational movements are required, such as:

- Tyre change: Loosening of wheel bolts and nuts

- Metal construction: Screwing long threaded screws into metal

- DIY projects: Screwing long screws into wood, e.g. in patio construction

Comparison: Impact Driver vs. (Impact) Drill Driver

Basically, impact drivers differ from (impact) drill drivers in that an impact driver is used only for screwing or screwing in and out screws and nuts, whereas a drill driver can screw with less force, but in addition, unlike the impact driver, can also drill.

Drill Driver

The cordless drill driver is probably the most common tool found in our households. It has two functions: Screwing and drilling, between which it is usually possible to choose. The performance of cordless drill drivers, i.e. torque and speed, can usually be adjusted so that drilling in wood or metal can be carried out easily. For harder material, however, the impact drill should be used.

Impact drill

The impact drill, like the impact wrench, works with one percussion motion. However, the blow is exerted axially by means of a cam percussion mechanism. This means that the impact is carried out in the direction of the wall when drilling into a wall. Thus, drilling or percussion drilling is possible with the percussion drill, even in harder materials such as masonry or brick. You can always select individually between the functions of screwing, drilling and impact drilling. Torque and speed can also be adapted to the material.

Impact wrenches

Loosening fixed screws - this is the parade discipline of an impact wrench. However, an impact wrench is only suitable for powerful screwing, more precisely for screwing in and unscrewing screws or for loosening nuts. This is mainly due to the mode of operation, namely the pulsating rotary movement, which is exerted by horizontal blows in the direction of the rotary movement, as a result of which an extremely high torque is generated. Depending on the model, the torque can be adjusted for all pneumatic impact wrenches or the IMPAXXO 18/400 cordless impact wrench. For example, it is the perfect device for the garage, where the tyre change takes place twice a year.

What should be considered when handling the impact wrench?

In principle, you can't do much wrong when dealing with an impact wrench. In general, you should be aware that you should not use an impact wrench to screw in conventional screws. For this purpose, there are cordless screwdrivers or cordless drill drivers, which you can also find in the Einhell range in numerous variants. So think about what tasks you really need such a high torque for, that the use of an electric, compressed air or cordless impact wrench makes sense.

If you want to screw in or unscrew a very stuck, possibly even rusted screw, it can happen that it "tears off" if too much force acts on the screw. You can prevent this by adjusting the torque correctly or carefully increasing it until the screw loosens. With our IMPAXXO 18/400, for example, you can choose between three speed levels that act on the screw with different torque levels.

If you turn a long screw into wood, for example, you should proceed with feeling. Because of the high force, it quickly happened that you screw the screw too deeply into the wood, which then frays around the screw head.